About Us

Quality Control

Views : 895

Update time : 2018-12-24 13:13:00

To ensure the quality of steel mesh, it is essential to implement strict control over raw materials, manufacturing processes, inspection standards, and quality management systems. The following are detailed measures to guarantee its quality:

- Specify the material grade (e.g., carbon steel Q235, stainless steel 304/316, aluminum alloy) based on application requirements, ensuring compliance with national standards (e.g., GB/T 700 for carbon steel).

- Require suppliers to provide material certificates (e.g., chemical composition, mechanical property reports) and conduct random sampling for physical and chemical tests (e.g., tensile strength, corrosion resistance).

Related News

Quality Control

Quality Control

Dec 24,2018

Quality is core value for every companny, xxxxx Hardware & Plastic has postivie feedback for quality products from customer by below actions:

•Each order is inspected and double-checked by QA as well as the Shipping Manager to insure quality and accuracy

•Strict ISO Standards are applied

•All products are under controlled for traceability

•Digital machine control are available

•Latest in quality control equipment

Quality Control

Quality Control

Dec 24,2018

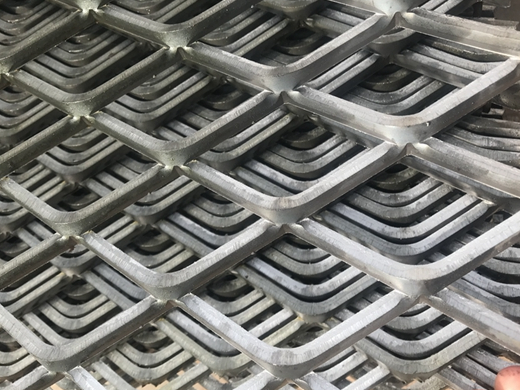

Use high-precision steel mesh punching and shearing machines with regular maintenance to ensure stable performance (e.g., mold alignment, punching pressure calibration).

Replace worn molds promptly to avoid inconsistent hole shapes or sizes.

Quality Control

Quality Control

Dec 24,2018

Establish a batch numbering system to track raw material sources, production dates, and process records for quality issue recall and analysis.